+86-13959205838

- essencreate@foxmail.com

+86-13959203868

- lemione5920@outlook.com

Room 209-3,No.14 Qishan Road,Huli District,Xiamen(361006)

+86-13959205838

+86-13959203868

Room 209-3,No.14 Qishan Road,Huli District,Xiamen(361006)

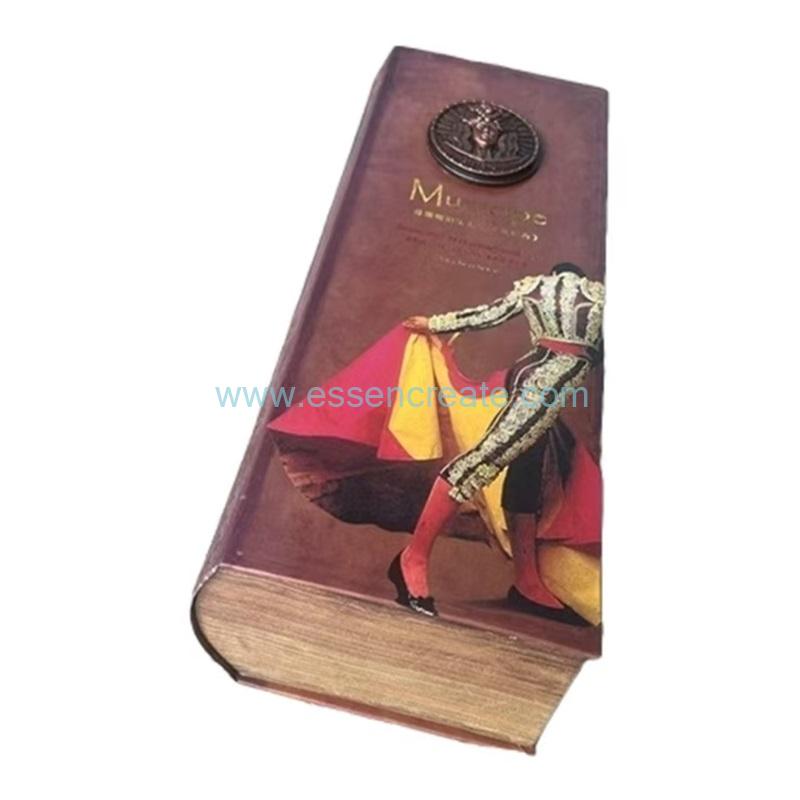

Folding Wine Box Packaging With Magnetic Lid Foldable Paper Box

Product Orgin:

chinaBrand:

EssenCreateItem NO.:

customShipping Port:

xiamenPayment:

T/TColor:

custom color

Folding Wine Box Packaging With Magnetic Lid Foldable Paper Box

The material processes for Cocktails wine glass packaging mainly include the following:

1.Flat printing: This is the most basic process for packaging wine glass boxes. Rich patterns and texts can be printed on the surface of the box. Commonly used materials include single copper paper, double copper paper, white cardboard, etc. Printing methods include offset printing, gravure printing, flexographic printing, etc.

2.Hot stamping: The metal foil or other materials are pressed on the surface of the box by heating to improve the texture and grade of the packaging, making the box more gorgeous and luxurious.

3.Embossed: The mold is used to apply pressure on the surface of the box to create convex, concave or patterned effects on the surface, enhancing the look and feel of the box. Commonly used materials include art paper, textured paper, leather cardboard, etc.

4.Beer grain: A texture effect similar to wood grain, usually used on the surface of the packaging box, to increase the texture and touch comfort, while reducing the appearance of fingerprints and other marks.

5.UV: UV ink is applied to the surface of the box and treated with ultraviolet light to increase gloss and moisture resistance, making the pattern fuller.

6.Hot stamping: Through the mold glue hot stamping lettering, patterns and other texture effects, the visual beauty is enhanced, and the grade and texture of the wine box are improved.

7.Laminating: Commonly there are matte film and glossy film. The matte film surface is not reflective, the texture is thick and high-end, and the glossy film has high transparency but interferes with vision.

8.Low-end wine box packaging process: Usually white board paper is used, and it is made through offset printing, hot stamping laminating, embossing, die-cutting and other processes, which is suitable for large batches and low costs.

9.Mid-range wine box packaging process: Aluminum foil cardboard (such as gold card, silver card, copper card, laser, etc.) is used, and it is made through screen printing, frosting, wrinkle glaze, pearl powder and other processes. The colors are bright and have various proprietary process effects.

10.High-end gift wine box packaging process: Aluminum foil cardboard is printed and then manually mounted on cardboard. The lining is mostly made of foam plastics, PVC blister electrostatic flocking, corrugated paper cards and other materials. Silk, chemical fiber fabrics, etc. can be used on the surface.

The selection of these processes and materials depends on the grade of the wine and market demand. High-end wine boxes usually use more complex and high-quality processes and materials, while low-end wine boxes focus on cost control and practicality.

prev:

Customizable Luxury Cardboard Wine Box Excellent Quality Custom Logo Paper Wine Bottle Packaging Gift GivingNext:

Deluxe Paper Gift Box Custom Printed Packing Single Bottle Folding Wine Box Packaging With Magnetic Lid Foldable Paper BoxFor customer service, including product information and order status, contact us at:

COMPLETE PACKAGING SUPPLIES & SOLUTIONS

Unable to find the product you need?

We support customization and supply complete packaging solutions.

Contact me and tell me your requests,we will help you customize satisfactory products.

One-stop Service. Quality is guaranteed. Professional,Worthy of Trust !

Skype: lemione5920@outlook.com